Relay Contact Welding: Causes, Prevention, and Replacement Strategies

페이지 정보

본문

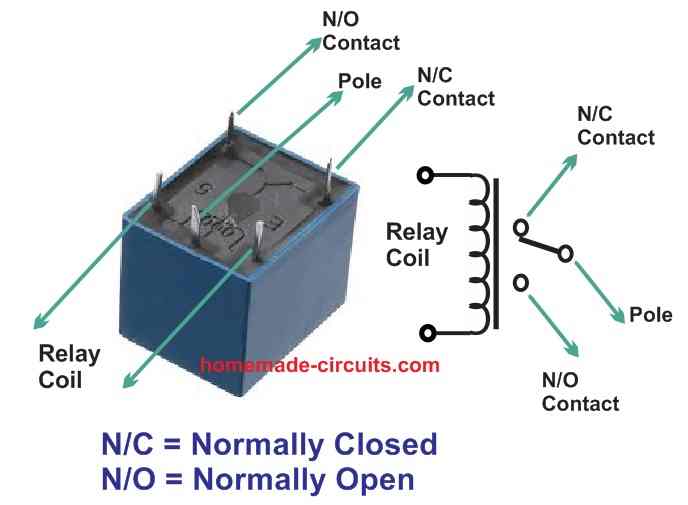

When relay contacts fuse together, it’s a typical breakdown scenario that occurs when the contacts stick together due to excessive heat or arcing during switching. This typically happens when a relay is used to switch high currents or when it is operated frequently under load. Prolonged electrical arcs cause the contact alloy to reach its melting point, causing it to fuse together. Once welded, the relay can no longer open the circuit, which may lead to unintended continuous operation or even potential fire hazards.

Welding is rarely due to a single issue. Overloading the relay beyond its rated current capacity is a primary cause. de-energizing under high current amplifies arc duration and promoting material transfer and fusion. Additionally, selecting a relay with inadequate specifications—such as a non-surge-rated device in capacitive or inductive circuits—can quickly lead to failure. Presence of conductive particulates can also shorten the operational lifespan of contacts.

To prevent contact welding, it is important to match the relay to the specific load demands. Use relays rated for the specific load type including DC, surge, or steady-state loads, and oversize the relay rating for safety. Consider using snubber circuits or varistors across inductive loads to dampen back-EMF surges. For systems with thousands of operations per hour, انواع رله SSRs offer superior reliability since they have no arcing-prone contacts.

If contact welding has already occurred, the relay is not serviceable on-site. The welded contacts are permanently fused, and attempting to manually separate them can cause dangerous arcing or shattering. The only reliable recovery method is to replace the relay with a new unit that is certified for the operating conditions. Always diagnose why the weld occurred to avoid future failures. Confirm excessive load demand using the wrong contact material, or missing snubbers or varistors.

Routine diagnostic assessments can help detect early signs of contact degradation, such as burn marks or material transfer, before welding occurs. Monitoring the relay’s operational cycles and comparing them to its expected lifespan can also help plan proactive replacements.

Understanding the causes and prevention of contact welding is essential for upholding safety and performance standards. Matching devices to load profiles and adding suppression circuits you can significantly reduce the risk of failure and maximize system uptime.

- 이전글How Cooking Techniques Affect Brown Rice Nutrition 25.10.09

- 다음글How to Choose the Best Online Slots Casino in Thailand 25.10.09

댓글목록

등록된 댓글이 없습니다.