Hydraulic Tank Filter Housing: The ultimate FAQ Information

페이지 정보

본문

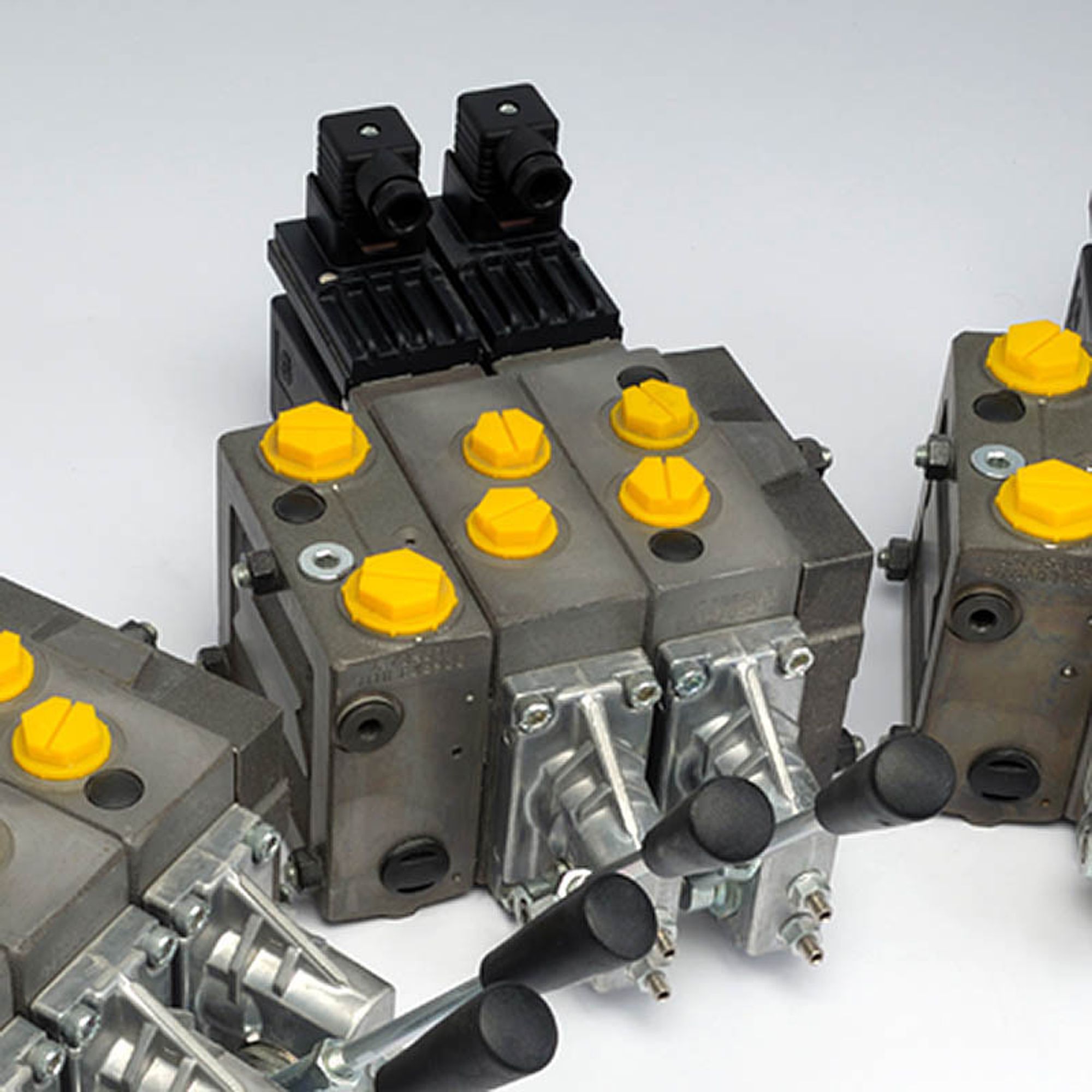

A wide range of bypass valve designs are available which provides you with options in selecting probably the most applicable hydraulic filter housing for your hydraulic methods. Bypass to tank, the design is made in a manner that it will enable the unfiltered bypass circulation again to the reservoir tank by way of a third port. Pneumatic tools use compressed air or gases to generate enough mechanical vitality in several industrial implementations, including blow guns, air tools, and decide-and-place functions. Pneumatic programs are ideal for situations that don't require the identical pressure that hydraulic pumps and methods usually generate. Since they don't have a whole lot of advanced shifting elements or depend on electricity, pneumatic tools are safer and easier to keep up than electric sources of power, and usually a lot cheaper. When a mission wants an vitality source with extra force or one that allows for higher accuracy, many firms flip to hydraulic power.

Their motors are generally present in material handling and agricultural gear. Char-Lynn, a brand within Eaton's Hydraulics Group, is renowned for its orbital hydraulic motors. These motors are valued for his or her compact design, reliability, and high torque output, making them appropriate for varied purposes. Hydraulic drive motors are pivotal parts in the machinery that drives our modern world. Understanding the working principles of these motors offers perception into their effectivity and reliability. With manufacturers like Vickers, Sauer Danfoss, Rexroth, White, and Char-Lynn persistently pushing the boundaries of hydraulic technology, the future of hydraulic drive motors promises continued innovation and enhanced efficiency across numerous industries. As technology evolves, these motors will doubtless play an even more vital position in powering the machinery that shapes our each day lives. A piston rod serves to couple the mechanical power generated inside the cylinder to the exterior load. Hydraulic linear motors are helpful for purposes that require a high-drive, straight-line movement and so are utilized as brake cylinders in vehicles, management actuators on aircraft, and in devices that inject molten metal into die-casting machines. A rotational motor, sometimes referred to as a rotary hydraulic motor, produces a rotary movement. In such a motor the pressurized fluid supplied by a hydraulic pump acts on the surfaces of the motor’s gear teeth, vanes, or pistons and creates a drive that produces a torque on the output shaft. Rotational motors are most often used in digging tools (e.g., earth augers), printing presses, and spindle drives on machine instruments.

These collectors include a series of rings or toroidal-shaped magnets assembled axially onto a metallic rod. Between the magnets are spacers where the magnetic gradient is the best, serving because the loading zone for the particles to collect. Periodically the rods are eliminated, inspected and wiped clear with a rag or lint-free cloth. A conceptual example of a specific rod magnet filter is shown in Determine 1. When the rod is eliminated, the sheath or shroud will be slid off the magnet core to take away the collected debris. They are available in lots of designs, fashions and displacements. Denison Hydraulics vane pumps are one of the strongest products in the business. Their unique double-lip design stands them apart in high quality. This enables the vane to be involved with the cam ring at two points as an alternative of just one. This also makes them much less prone to contamination. Denison Hydraulics provides a spread of hydraulic vane pumps, various in size, pressure and displacement. Hydraulic filtration tanks, i.e., hydraulic filtration tanks, play an important function in the hydraulic system. They are primarily used to store and filter hydraulic oil, make sure the cleanliness of the hydraulic oil, and thus protect the assorted components within the hydraulic system from contamination and wear. Storing Hydraulic Oil: Gives a stable provide of hydraulic oil to the hydraulic system.

Pumps serve the identical fundamental function in all contexts where hydraulic machinery is used: they transport hydraulic fluid from one location to another with the intention to generate hydraulic power and stress (along with the actuators). Elevators, automotive brakes, automotive lifts, cranes, airplane flaps, shock absorbers, log splitters, motorboat steering programs, garage jacks and different products use hydraulic pumps. Seal glands sometimes comprise a major seal, secondary seal/buffer seal, bearing components, wiper/scraper, and static seal. In some cases, particularly in small hydraulic cylinders, the rod gland and bearing components are made from a single integral machined part. Hydraulic seals, like the hydraulic cylinder itself, are specified based mostly on cylinder working pressure, cylinder pace, working temperature, and software. Seals used on hydraulic cylinders are dynamic and must be able to stand up to the wear of the piston rod extending and retracting. Seals are usually made from nitrile rubber, Polyurethane or Teflon, and are finest in lower temperature environments. Fluorocarbon are a better possibility. Metallic seals are additionally available and generally use bronze for the seal materials.

Hydraulic pumps are notably designed machines utilized in industrial, industrial, and residential areas to generate helpful energy from totally different viscous liquids pressurization. Hydraulic pumps are exceptionally easy but efficient machines for shifting fluids. Hydraulic pumps rely on the power offered by hydraulic cylinders to energy different machines and mechanisms. There are a number of different types of hydraulic pumps, and all hydraulic pumps could be break up into two major classes. Modular designs will allow easier customization primarily based on specific necessities. Variable Pace Drives: Rather than working hydraulic pumps at a relentless velocity, variable velocity drives adjust the pump’s operation based mostly on the system’s demand. This leads to important power savings and diminished wear. Integration with Advanced Management Techniques: With advancements in management methods, future pumps could have higher synchronization with different system parts, resulting in smoother operation and elevated efficiency.

- 이전글2024년 한국에서 가장 인기있는 카지노사이트와 바카라사이트 TOP 7 24.10.13

- 다음글9 Lessons Your Parents Teach You About Mesothelioma Asbestos Lawyers 24.10.13

댓글목록

등록된 댓글이 없습니다.